Quality can be largely perceived as a subjective term, and is dependent on analysts’ perception. There are many definitions for general quality management systems. Most of them in recent times emphasize the use of some type of system that is repeatable, measurable and constantly improving.

Quality can be largely perceived as a subjective term, and is dependent on analysts’ perception. There are many definitions for general quality management systems. Most of them in recent times emphasize the use of some type of system that is repeatable, measurable and constantly improving.

The concept of a quality as we practice now first emerged from the Industrial Revolution. Previously goods had been made from start to finish by the same person or team of people, with handcrafting and tweaking the product to meet certain criteria called ‘quality criteria’. Few copies of a product were made initially as a test run called limited editions and then large masses of similar products were produced, which were termed Mass Production. Mass production brought huge teams of people together to work on specific stages of production where one person would not necessarily complete a product from start to finish. In the late 19th century pioneers such as Frederick Winslow Taylor and Henry Ford recognized the limitations of the methods being used in mass production [Quality Assurance] at the time and the subsequent varying quality of output. Birland established Quality Departments to oversee the quality of production and error rectification [Quality Control], and Ford stressed on standardization of design and component standards to ensure a standard product was produced. Management of quality was the responsibility of the Quality department and was implemented by Inspection of product output to ‘catch’ defects [Quality Control]

Application of statistical control came later as a result of World War production methods, which were advanced by the work done of W. Edwards Deming, a statistician, after whom the Deming Prize for quality is named. Joseph M. Juran focused more on managing for quality. The first edition of Juran’s Quality Control Handbook was published in 1951. He also developed the “Juran’s trilogy”, an approach to cross-functional management that is composed of three managerial processes: Quality planning, Quality control, and Quality improvement. These functions all play a vital role when evaluating quality.

Quality, as a profession and the managerial process associated with the quality function, was introduced during the second half of the 20th century and has evolved since then. Over this period, few other disciplines have seen as many changes as the quality profession.

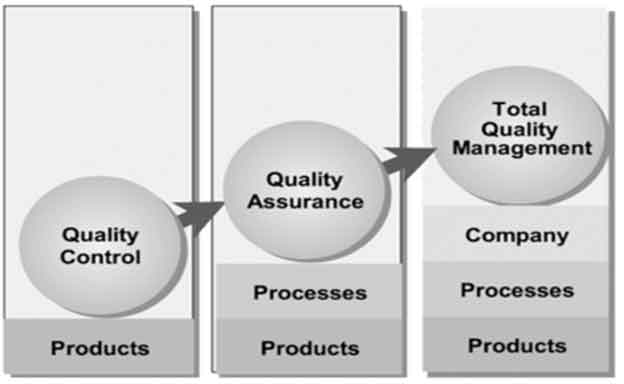

The quality profession grew from simple control to engineering, to systems engineering. Quality control activities were predominant in the 1940s, 1950s, and 1960s. The 1970s were an era of quality engineering and the 1990s saw quality systems as an emerging field. Like medicine, accounting, and engineering, quality has achieved status as a recognized profession.

Recently, we talk about Total Quality Management, where emphasis are made on Company, Processes and Products. We assume a holistic poise with identification of root causes and applicable trusted principles to address issues of inconsistency, susceptibility, longevity to mention but a few in the Nigerian context. For instance, how many indigenous industries has scaled beyond a hundred years…. The Key is as displayed diagrammatically below.

The New Experience Newspapers Online News Indepth, Analysis and More

The New Experience Newspapers Online News Indepth, Analysis and More